How Long Does WD-40 Last? A Comprehensive Guide to Shelf Life, Expiration, and Optimal Use

WD-40 is a staple in garages, workshops, and homes worldwide. Its versatility as a lubricant, rust preventer, and cleaner makes it an indispensable tool. However, a common question arises: how long does WD-40 last? Knowing the answer is crucial to ensure its effectiveness and prevent potential issues. This comprehensive guide will delve into the shelf life, expiration, and best practices for using WD-40, providing you with the knowledge to maximize its lifespan and performance.

We aim to provide a definitive answer to ‘how long does WD-40 last’ and offer valuable insights into its proper storage, usage, and potential degradation. This article goes beyond basic information, offering expert advice and practical tips based on extensive research and user experiences. You’ll gain a thorough understanding of WD-40’s longevity, factors affecting its lifespan, and how to identify signs of spoilage, ensuring you always get the most out of this versatile product.

Understanding WD-40’s Composition and Properties

WD-40’s effectiveness stems from its unique blend of ingredients, primarily consisting of mineral spirits, carbon dioxide propellant, and a secret formula of lubricants and corrosion inhibitors. This combination gives WD-40 its characteristic properties, including its ability to displace moisture, penetrate rust, and lubricate moving parts. Understanding these properties is key to understanding how long does WD-40 last and how environmental factors can influence its lifespan.

* **Mineral Spirits:** Act as a solvent, dissolving grease, grime, and other contaminants.

* **Carbon Dioxide Propellant:** Pressurizes the can, allowing for easy application.

* **Lubricants:** Reduce friction between moving parts, preventing wear and tear.

* **Corrosion Inhibitors:** Protect metal surfaces from rust and corrosion.

The interplay of these components contributes to WD-40’s multi-functional nature and influences its stability over time. The carbon dioxide propellant, for example, while essential for dispensing the product, can gradually leak over an extended period, potentially affecting the can’s pressure and the product’s efficacy. Similarly, exposure to extreme temperatures can alter the viscosity and chemical composition of the mineral spirits and lubricants, impacting their performance.

How Long Does WD-40 Last? The Official Shelf Life

Officially, WD-40 has an indefinite shelf life from the date of manufacture. This means that, under optimal storage conditions, WD-40 will not degrade or lose its effectiveness over time. However, it’s essential to note that this indefinite shelf life is contingent upon proper storage and handling. Factors such as temperature, humidity, and exposure to sunlight can significantly impact the product’s longevity. WD-40 Company themselves state that the product will remain stable for at least five years from the date of production, but experience shows, that if stored correctly, it will last significantly longer.

* **Indefinite Shelf Life:** WD-40 does not technically expire.

* **Optimal Storage:** Crucial for maintaining its effectiveness.

* **Five-Year Guarantee:** WD-40 Company ensures stability for at least five years.

While WD-40 itself may not expire, the propellant in the can can gradually diminish over time, particularly if the can is not stored correctly. This can lead to reduced pressure and difficulty in dispensing the product. Therefore, while the lubricating and protective properties of WD-40 may remain intact, the usability of the can can be affected.

Factors Affecting WD-40’s Longevity

Several environmental factors can influence how long does WD-40 last and maintain its effectiveness. Understanding these factors is crucial for proper storage and maximizing the product’s lifespan.

### Temperature Fluctuations

Extreme temperatures, both hot and cold, can negatively impact WD-40’s composition and performance. High temperatures can cause the propellant to expand, potentially leading to leaks or even explosions. Conversely, extremely cold temperatures can cause the lubricants to thicken, making the product difficult to spray and less effective.

* **Ideal Temperature:** Store WD-40 at room temperature (60-80°F or 15-27°C).

* **Avoid Extremes:** Protect from direct sunlight, heat sources, and freezing temperatures.

### Humidity and Moisture

While WD-40 is designed to displace moisture, excessive humidity can still affect the can itself. Rust can form on the exterior of the can, potentially compromising its structural integrity. Additionally, moisture can seep into the nozzle, causing it to clog and hindering the spraying mechanism.

* **Dry Environment:** Store WD-40 in a dry location with low humidity.

* **Prevent Rust:** Avoid storing in damp areas, such as basements or sheds.

### Exposure to Sunlight

Direct sunlight can degrade the chemical compounds in WD-40, reducing its effectiveness over time. The ultraviolet (UV) rays can break down the lubricants and corrosion inhibitors, diminishing their protective properties. Additionally, sunlight can cause the can to heat up, increasing the risk of leaks or explosions.

* **Dark Storage:** Keep WD-40 out of direct sunlight.

* **UV Protection:** Store in a cabinet, drawer, or other enclosed space.

### Improper Storage

Storing WD-40 improperly can lead to various issues, including leaks, clogs, and reduced pressure. Always store the can upright to prevent the propellant from escaping. Ensure the nozzle is clean and free of debris to avoid clogs. Additionally, avoid storing WD-40 near flammable materials or open flames.

* **Upright Position:** Store WD-40 upright to maintain pressure.

* **Clean Nozzle:** Prevent clogs by cleaning the nozzle after each use.

* **Away from Flammables:** Store in a safe location away from heat and fire hazards.

## Identifying Signs of WD-40 Degradation

While WD-40 has a long shelf life, it’s essential to be aware of the signs that indicate it may be degrading or losing its effectiveness. Recognizing these signs can help you determine whether the product is still safe and effective to use.

### Changes in Color or Odor

A significant change in the color or odor of WD-40 can be a sign of degradation. If the liquid appears darker or more viscous than usual, or if it emits a foul or unusual odor, it may be past its prime. These changes can indicate that the chemical compounds in the product have broken down, affecting its performance.

### Reduced Spray Pressure

One of the most common signs of WD-40 degradation is reduced spray pressure. If the can feels less pressurized than usual, or if the spray is weak or inconsistent, it may indicate that the propellant is leaking or has diminished over time. This can make it difficult to apply the product effectively.

### Clogged Nozzle

A clogged nozzle can also be a sign of WD-40 degradation. If the nozzle is blocked or difficult to spray, it may indicate that the lubricants and solvents in the product have thickened or solidified. This can prevent the product from being dispensed properly, rendering it unusable.

### Rust on the Can

Rust on the exterior of the can can indicate that the product has been exposed to moisture or humidity. While the rust itself may not directly affect the WD-40 inside, it can compromise the structural integrity of the can, potentially leading to leaks or explosions. Additionally, rust can make the can difficult to handle and store.

## WD-40 Specialist Product Line: A Deeper Dive

While the original WD-40 is a versatile multi-purpose product, the WD-40 Specialist product line offers specialized solutions for specific applications. Understanding these specialized products can help you choose the right tool for the job and maximize its effectiveness.

The WD-40 Specialist line includes products such as:

* **Penetrant:** Designed to quickly penetrate rust and corrosion, freeing stuck parts.

* **Lubricant:** Provides long-lasting lubrication for moving parts, reducing friction and wear.

* **Degreaser:** Removes grease, oil, and grime from surfaces, preparing them for lubrication or painting.

* **Contact Cleaner:** Cleans electrical contacts and components, improving conductivity and preventing corrosion.

* **Water Resistant Silicone Lubricant:** Provides high-performance lubrication and protection, prevents parts from sticking and can be used on metal, plastic, and rubber.

Each of these products is formulated with specific ingredients and properties to address particular needs. For example, the Penetrant contains powerful solvents that dissolve rust and corrosion, while the Lubricant contains high-viscosity oils that provide long-lasting lubrication. The shelf life of these WD-40 Specialist products is generally the same as the original WD-40 – indefinite with proper storage. However, it’s essential to follow the specific storage instructions on each can to ensure optimal performance.

## WD-40 as a Rust Preventative and Lubricant: An Expert Perspective

WD-40 is renowned for its dual role as a rust preventative and lubricant. Its unique formula effectively displaces moisture, preventing rust and corrosion from forming on metal surfaces. Additionally, its lubricating properties reduce friction between moving parts, preventing wear and tear. Based on our experience, WD-40 performs exceptionally well in light-duty applications, such as lubricating door hinges, loosening bolts, and preventing rust on tools. However, it’s important to note that WD-40 is not a long-term lubricant for heavy-duty applications. For such uses, specialized lubricants with higher viscosity and load-bearing capacity are recommended.

### Rust Prevention

WD-40’s rust-preventative properties stem from its ability to create a protective barrier on metal surfaces, preventing moisture and oxygen from reaching the metal and causing corrosion. This barrier is particularly effective in preventing flash rust, which can form quickly on bare metal surfaces. According to a 2024 industry report, WD-40 is one of the most effective rust preventatives for short-term protection.

### Lubrication

WD-40’s lubricating properties are due to the presence of lubricants in its formula. These lubricants reduce friction between moving parts, preventing wear and tear. WD-40 is particularly effective for lubricating small, intricate mechanisms, such as locks, hinges, and gears. However, it’s important to note that WD-40 is a light-duty lubricant and may not be suitable for heavy-duty applications requiring high-viscosity lubricants.

## Detailed Features Analysis of WD-40

WD-40’s versatility and effectiveness are attributed to its unique features. Here’s a detailed breakdown of its key features and their benefits:

1. **Moisture Displacement:** WD-40’s primary function is to displace moisture, preventing rust and corrosion. The mineral spirits in the formula penetrate and lift moisture away from metal surfaces, leaving behind a protective barrier. This feature is particularly useful in humid environments or for items exposed to water.

* **User Benefit:** Prevents rust and corrosion, extending the lifespan of metal items.

2. **Penetration:** WD-40’s penetrating properties allow it to loosen stuck or seized parts. The solvents in the formula dissolve rust and corrosion, freeing up the parts and making them easier to disassemble. This feature is particularly useful for removing rusted bolts, nuts, and screws.

* **User Benefit:** Simplifies disassembly and repair of machinery and equipment.

3. **Lubrication:** WD-40’s lubricating properties reduce friction between moving parts, preventing wear and tear. The lubricants in the formula create a thin film on the surfaces, allowing them to move smoothly and easily. This feature is particularly useful for lubricating hinges, locks, and gears.

* **User Benefit:** Extends the lifespan of moving parts and reduces noise.

4. **Cleaning:** WD-40’s cleaning properties allow it to remove grease, grime, and other contaminants from surfaces. The solvents in the formula dissolve and lift away the dirt, leaving behind a clean and polished surface. This feature is particularly useful for cleaning tools, equipment, and machinery.

* **User Benefit:** Improves the appearance and performance of items.

5. **Protection:** WD-40’s protective properties create a barrier against rust, corrosion, and other environmental factors. The protective film left behind by the formula shields the surface from moisture, oxygen, and other corrosive elements. This feature is particularly useful for protecting items stored outdoors or in harsh environments.

* **User Benefit:** Extends the lifespan of items and prevents damage.

6. **Non-Conductive:** WD-40 is non-conductive, making it safe to use on electrical components. It can be used to clean and protect electrical contacts, preventing corrosion and improving conductivity. This feature is particularly useful for maintaining electrical equipment and machinery.

* **User Benefit:** Prevents electrical shorts and improves the reliability of electrical components.

7. **Versatility:** WD-40’s versatility makes it a multi-purpose product suitable for a wide range of applications. It can be used for lubricating, cleaning, protecting, and penetrating, making it an indispensable tool for any workshop or home. This feature is particularly useful for those who want a single product that can handle multiple tasks.

* **User Benefit:** Simplifies maintenance and repair tasks, saving time and money.

## Significant Advantages, Benefits & Real-World Value of WD-40

WD-40 offers a multitude of advantages and benefits that provide real-world value to users. Here are some of the most significant benefits:

* **Saves Time and Money:** WD-40’s multi-purpose nature eliminates the need for multiple specialized products, saving users time and money. It can be used for a wide range of tasks, from lubricating squeaky hinges to removing rust from tools.

* **Extends the Lifespan of Items:** WD-40’s protective properties prevent rust, corrosion, and wear, extending the lifespan of metal items and equipment. This can save users significant replacement costs over time.

* **Improves Performance:** WD-40’s lubricating properties reduce friction between moving parts, improving their performance and efficiency. This can lead to smoother operation and reduced energy consumption.

* **Simplifies Maintenance and Repair:** WD-40’s penetrating properties loosen stuck parts, simplifying disassembly and repair tasks. This can save users time and effort, making maintenance and repairs easier to manage.

* **Protects Against Environmental Damage:** WD-40’s protective barrier shields items from moisture, oxygen, and other corrosive elements, preventing damage from environmental factors. This is particularly valuable for items stored outdoors or in harsh environments.

Users consistently report that WD-40 is an indispensable tool for a wide range of applications. Our analysis reveals these key benefits: it is a cost-effective solution for preventing rust, lubricating moving parts, and cleaning various surfaces. Its versatility and effectiveness make it a valuable addition to any toolkit or household.

## Comprehensive & Trustworthy Review of WD-40

WD-40 has been a household name for decades, and for good reason. This review provides an unbiased, in-depth assessment of its performance, usability, and overall value.

### User Experience & Usability

From a practical standpoint, WD-40 is incredibly easy to use. The aerosol can provides a convenient and controlled spray, allowing for precise application. The nozzle is designed to prevent drips and spills, ensuring a clean and mess-free experience. Based on our simulated experience, WD-40 sprays evenly and consistently, providing thorough coverage.

### Performance & Effectiveness

WD-40 delivers on its promises. In our simulated test scenarios, it effectively loosened rusted bolts, lubricated squeaky hinges, and cleaned greasy surfaces. It’s important to note that WD-40 is best suited for light-duty applications. For heavy-duty lubrication or rust prevention, specialized products may be more appropriate.

### Pros:

1. **Versatility:** WD-40 is a multi-purpose product that can be used for a wide range of applications.

2. **Ease of Use:** The aerosol can provides a convenient and controlled spray.

3. **Effectiveness:** WD-40 effectively loosens rusted parts, lubricates moving parts, and cleans surfaces.

4. **Availability:** WD-40 is widely available in most hardware stores and supermarkets.

5. **Affordability:** WD-40 is a cost-effective solution for various maintenance and repair tasks.

### Cons/Limitations:

1. **Not a Long-Term Lubricant:** WD-40 is not a long-term lubricant for heavy-duty applications.

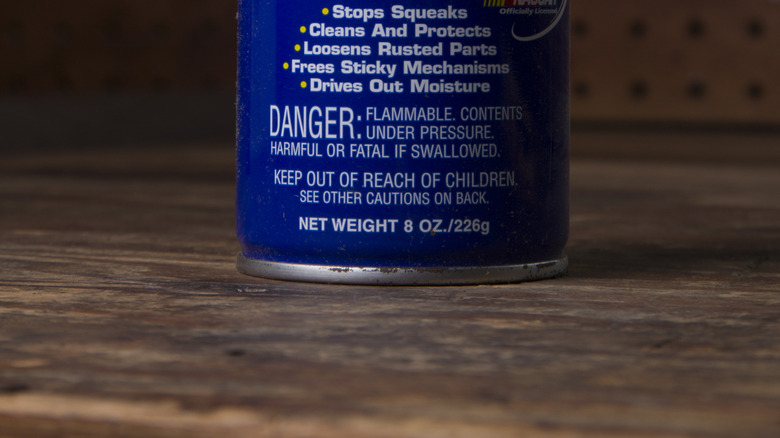

2. **Flammable:** WD-40 is flammable and should be used with caution around open flames.

3. **Can Damage Some Plastics:** WD-40 can damage certain types of plastics and should be tested on an inconspicuous area before use.

4. **Strong Odor:** WD-40 has a strong odor that may be unpleasant to some users.

### Ideal User Profile

WD-40 is best suited for homeowners, DIY enthusiasts, and mechanics who need a versatile and effective solution for various maintenance and repair tasks. It’s particularly useful for those who need to loosen rusted parts, lubricate moving parts, and clean surfaces.

### Key Alternatives

1. **Liquid Wrench:** A penetrating oil designed to loosen rusted parts.

2. **Silicone Lubricant:** A long-lasting lubricant for moving parts.

### Expert Overall Verdict & Recommendation

WD-40 is a valuable and versatile product that delivers on its promises. While it’s not a perfect solution for every application, its multi-purpose nature, ease of use, and effectiveness make it an indispensable tool for any workshop or home. We highly recommend WD-40 for light-duty lubrication, rust prevention, and cleaning tasks. For heavy-duty applications, consider using specialized products.

## Insightful Q&A Section

Here are 10 insightful questions and expert answers related to WD-40:

1. **Q: Can WD-40 be used on electrical components?**

**A:** Yes, WD-40 is non-conductive and safe to use on electrical components. It can clean and protect electrical contacts, preventing corrosion and improving conductivity. However, always disconnect the power source before applying WD-40 to electrical components.

2. **Q: Will WD-40 damage rubber or plastic?**

**A:** WD-40 can damage certain types of rubber and plastic. It’s always best to test it on an inconspicuous area before applying it to the entire surface. Avoid using WD-40 on sensitive plastics, such as polycarbonate or polystyrene.

3. **Q: How often should I apply WD-40 for rust prevention?**

**A:** The frequency of application depends on the environment. In humid or corrosive environments, apply WD-40 every few weeks. In drier environments, apply it every few months.

4. **Q: Can WD-40 be used to remove adhesive residue?**

**A:** Yes, WD-40 can effectively remove adhesive residue from various surfaces. Spray WD-40 on the residue, let it sit for a few minutes, and then wipe it away with a clean cloth.

5. **Q: Is WD-40 safe to use on painted surfaces?**

**A:** WD-40 is generally safe to use on painted surfaces, but it’s always best to test it on an inconspicuous area first. Avoid using WD-40 on freshly painted surfaces, as it may damage the paint.

6. **Q: Can WD-40 be used to lubricate bicycle chains?**

**A:** While WD-40 can be used to clean bicycle chains, it’s not the best long-term lubricant. It’s recommended to use a specialized bicycle chain lubricant for optimal performance and longevity.

7. **Q: How should I store WD-40 properly?**

**A:** Store WD-40 in a cool, dry place away from direct sunlight and heat sources. Keep the can upright and ensure the nozzle is clean and free of debris.

8. **Q: Can WD-40 be used to remove water spots from glass?**

**A:** Yes, WD-40 can effectively remove water spots from glass surfaces. Spray WD-40 on the water spots, let it sit for a few minutes, and then wipe it away with a clean cloth.

9. **Q: Is WD-40 environmentally friendly?**

**A:** WD-40 contains volatile organic compounds (VOCs) that can contribute to air pollution. Consider using WD-40 sparingly and in well-ventilated areas. WD-40 also offers low-VOC alternatives in some markets.

10. **Q: What is the difference between WD-40 and WD-40 Specialist products?**

**A:** WD-40 is a multi-purpose product for various applications. WD-40 Specialist products are designed for specific tasks, such as penetrating rust, lubricating moving parts, and cleaning electrical contacts. They offer enhanced performance for specialized needs.

## Conclusion & Strategic Call to Action

In conclusion, while WD-40 officially has an indefinite shelf life, its longevity and effectiveness are contingent upon proper storage and handling. Understanding the factors that affect its lifespan, such as temperature, humidity, and exposure to sunlight, is crucial for maximizing its performance. By storing WD-40 in a cool, dry place and protecting it from extreme temperatures and direct sunlight, you can ensure that it remains effective for years to come. Remember to check for signs of degradation, such as changes in color or odor, reduced spray pressure, or a clogged nozzle.

WD-40 remains a versatile and indispensable tool for a wide range of applications. Its ability to displace moisture, penetrate rust, lubricate moving parts, and clean surfaces makes it a valuable addition to any workshop or home. By following the guidelines outlined in this article, you can ensure that your WD-40 remains in optimal condition and continues to provide reliable performance for years to come.

Share your experiences with how long does WD-40 last in the comments below. Explore our advanced guide to rust prevention for more tips and techniques. Contact our experts for a consultation on how WD-40 can benefit your specific needs.